Fäden der Innovation: So entsteht unser reflektierendes Gurtband

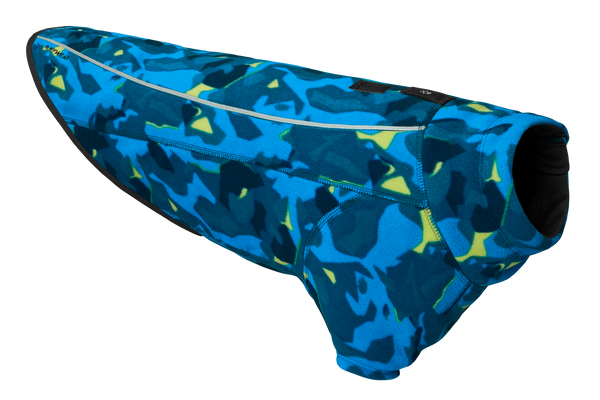

Aus Neugier entdeckte Ruffwear-Produktdesignerin Monica eine Möglichkeit, Jacquardgewebe mit reflektierenden Elementen zu versehen. Das Ergebnis: reflektierende Leinen und Halsbänder in auffälligen und langlebigen Mustern.

Bevor wir uns in die neuen Muster für die Saison vertiefen, fragen Sie sich vielleicht: Was ist Jacquardgewebe?

Jacquardgewebe wird in einem speziellen Webverfahren hergestellt. Es handelt sich um einen komplizierten Prozess, der spezielle Maschinen und besonderes Können der Arbeiter erfordert, die das Gewebe herstellen. Es ist zeitaufwändiger und arbeitsintensiver als eine einfache Webart, aber die Vorteile von Jacquardgewebe eignen sich gut für die Anforderungen unserer Halsbänder und Gewebe.

Da das Design in das Gewebe integriert und nicht darauf gedruckt ist, verblasst es nicht und reibt sich auch nicht ab. Und bei Hunden ist Abrieb definitiv ein Problem. Außerdem können die Designs komplexer sein – was nützlich ist, wenn wir versuchen, einige unserer Lieblingslandschaften und Naturelemente darzustellen.

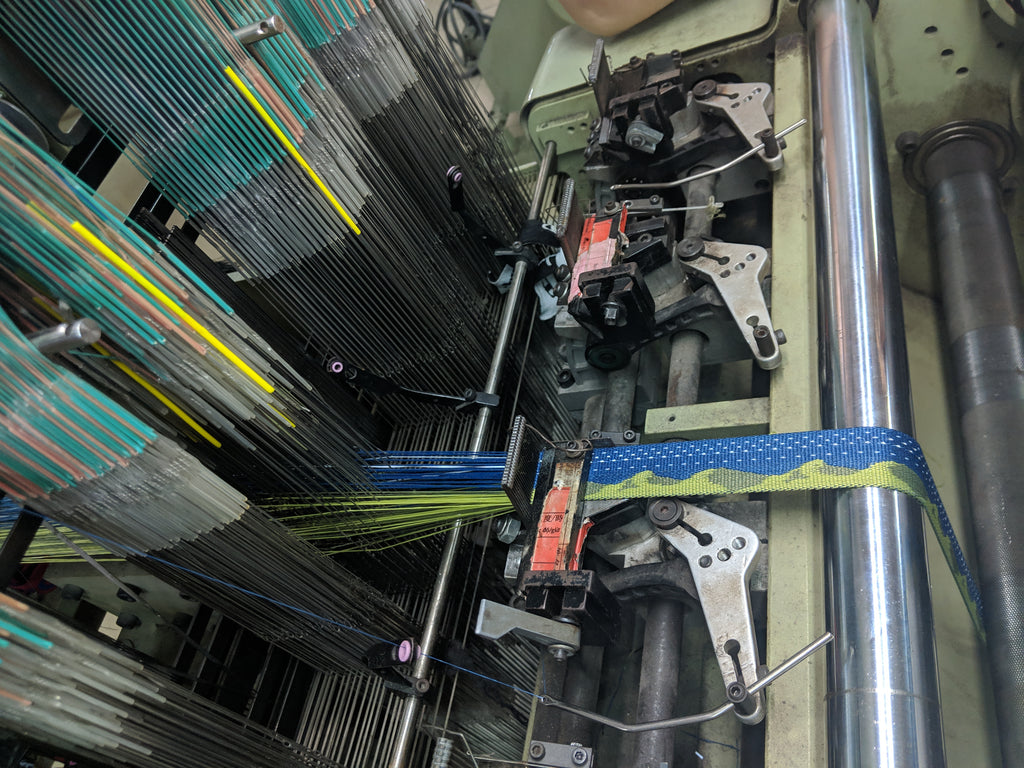

Es ist verlockend, reflektierende Fäden in das Gurtband zu integrieren – auch hier, weil sie haltbarer sind, als wenn sie auf das Gurtband gedruckt wären. Aber die Einführung von Reflektivität in einen ohnehin schon komplizierten Prozess bedeutete, dass uns viele Hersteller anfangs „Nein“ sagten, als wir uns auf diesen Weg begaben.

Bei einem typischen Jacquardgewebe wird der gleiche Fadentyp verwendet, sodass alles irgendwie zusammenpasst. Die Maschine muss je nach verwendetem Fadentyp eine bestimmte Spannungseinstellung haben. Zwei verschiedene Fadentypen (z. B. reflektierend und nicht reflektierend) bedeuten zwei verschiedene Spannungseinstellungen, und das macht es superknifflig.

Wir haben gemeinsam mit unseren Partnern die richtigen Einstellungen ermittelt, damit es funktioniert. Allerdings müssen sie die Maschinen trotzdem langsamer laufen lassen als sonst und den Status der Fäden überwachen, um sicherzustellen, dass nichts reißt – oder umgekehrt, dass die Fäden nicht straff genug sind, was die Haltbarkeit gefährden würde.

Mit dieser neuen Welt der Möglichkeiten begann Monica, neue Muster zu entwickeln und reflektierende Akzente in das Design zu integrieren. Ihre Inspiration? Sie betrachtete die verschiedenen Arten, wie Licht auf natürliche Weise in unseren Lieblingslandschaften auftritt und mit ihnen spielt.

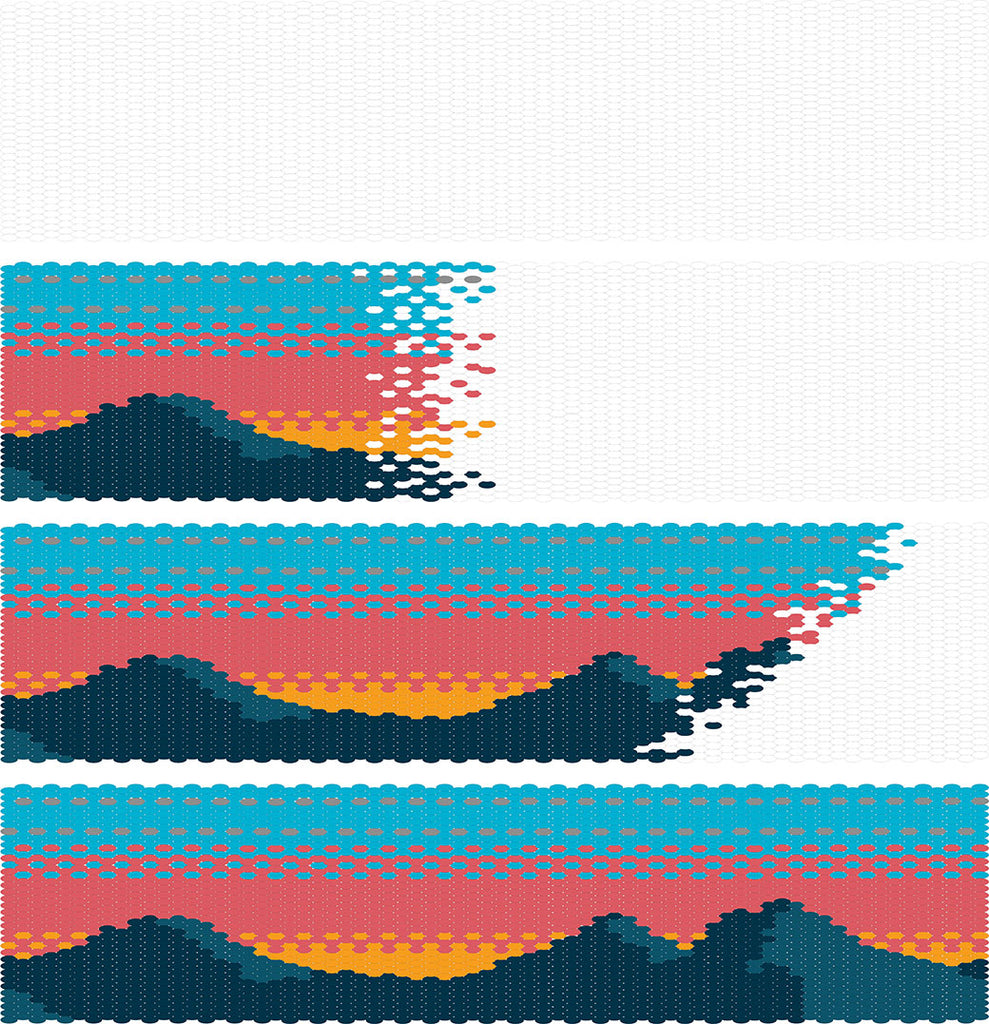

Von dort aus überträgt sie grobe Skizzen und Ideen in eine leere Grafik mit Zellen, die jeden Schuss (auf der Vorderseite eines Gewebes ist jede Quer- oder Webrichtung ein Schuss) in einem Abschnitt des Gewebes darstellen. Hier sehen Sie den Prozess für einen der neuen Drucke, Sunset.

Es gibt unzählige andere Dinge, die hinter den Kulissen passieren, während Monica ein Muster entwickelt und es in seine endgültige Form bringt, die Sie am Halsband oder an der Leine Ihres Hundes sehen. Aber dafür müssten wir uns wirklich in die Materie vertiefen (oder weben).

Nachdem Sie nun ein wenig mehr über unsere Anfänge und unseren Weg hierher wissen, wollen wir uns die neuen Muster für das Crag Collar und die Crag Leash sowie die Inspiration dahinter genauer ansehen.

MEERESSCHAUM

Inspiriert von leuchtendem biolumineszierendem Phytoplankton, das in der Gezeitenströmung entlang der Küsten des pazifischen Nordwestens vorkommt.

SONNENUNTERGANG

Inspiriert vom wechselnden Licht und den Farbtönen, wenn die Sonne hinter den Three Sisters versinkt – der ikonischen Berglandschaft in unserem Hinterhof.

GRÜNE HÜGEL

Inspiriert von Sternen, die am dunklen Himmel über der hügeligen Landschaft der Appalachen erscheinen.