Diving Into the Deep, bluesign® Sea

COMMITTED TO PERFORMANCE. COMMITTED TO SUSTAINABILITY.

As a company dedicated to making great gear, our definition of success includes embracing our responsibility to both our community and our planet.

Sometimes stated as "doing well by doing good," we’re conducting our business in a way that maximizes the good we can do in the world while being mindful of the impact we have on the environment.

We love hearing questions from you – our community – about what action we’re taking to do so. We’re committed to being transparent as we discover the nitty-gritty details of our impact as a brand, so keep the questions coming.

Our sit-down with our Sustainability Coordinator back in October is a good place to start if you’re wanting a big-picture view of our plan. Today, we’re going to dig deeper into one facet of our sustainability strategy: bluesign® materials.

LET’S ZOOM OUT FOR A SECOND

We’ll get back to what this has to do with your dog’s gear in a moment, but first, let’s get some context.

The textile industry is big. 62 million tons, big. That’s the estimated consumption of textiles back in 2015, with a shocking amount of it eventually being landfilled or incinerated (1 garbage truck full every second).

And the textile industry can be dirty. Chemicals, waste, pollutants, resource depletion, hazardous working conditions. When you consider how those 62 million tons are manufactured, the cost – to both the environment and humans – is staggering.

It’s overwhelming. We get it. The good news is there’s also growth in the efforts to choose ethical, sustainable methods over the toxic and harmful ones. And we’re committed to that effort. But how can you tell when a company chooses the sustainable path?

Enter bluesign® technologies. This is where you can picture a team of chemical experts, systems specialists, manufacturing gurus, and production pros – all probably wearing superhero capes – changing the world by changing the environmental and social impacts of manufacturing textiles, and helping more and more brands do so.

DIVING INTO THE DEEP BLUESIGN® SEA

bluesign® was established back in 2000. The team works independently to trace and verify a material’s path along every step of the manufacturing process – from chemicals, fibers, and dyes to the final product and the hands that craft them. It’s a complex journey, but that depth of assessment is what leads to greater transparency and the ability to improve.

They assess facilities for chemicals management competency, waste, and recycle stream proficiency. More importantly, they act as a resource for those facilities, working together to improve efficiency and safety across their operation.

Because of their stringent certification process, you can count on materials coming out of bluesign® certified facilities to be safer and more sustainable for the environment, workers, and you.

HOW DO THEY DO IT?

For a bluesign® approved fabric, it all starts at the textile mill. bluesign® auditors rate the mill’s air and water impact, listing areas of concern and guiding them towards sustainable alternatives (like organic and recycled fibers, eco-friendly dyes and chemicals, and wastewater and chemical recycling). They must meet strict standards for pollution control.

bluesign® also consults about their manufacturing processes – the more efficient a facility can operate, the more they can reduce overall water, energy, and chemical use.

bluesign® works with these facilities to implement safety features and oversee labor practices throughout the production process to help protect workers. Their extremely strict chemical safety requirements for textiles further protect the workers (and even the end-consumer) from exposure to harmful chemicals.

The same standards are applied in bluesign® certified factories that then carry out the production process for brands that are bluesign® system partners.

SO, ABOUT THAT DOG GEAR...

While Ruffwear as a brand is not a bluesign® system partner at this point, we pursue supplier relationships with bluesign® certified facilities when sourcing materials for the gear we build.

When we evaluate materials as part of our design process, bluesign® certification and environmental impact are considered right alongside performance. It’s not performance over sustainability or sustainability over performance – we strive for both.

Where are we now?

Currently, you can find at least one bluesign® approved component (either a fabric or hardware) in 36 of our current styles (roughly 39%). And 20 of those are using bluesign® approved fabric, like in the Front Range™ Harness.

bluesign® approved fabrics account for about 28% of the volume of our material consumption (in yards). bluesign® approved components account for about 59% of our plastic hardware consumption (in number of pieces).

We’re improving upon that number during every design phase, and setting milestones to hit each year.

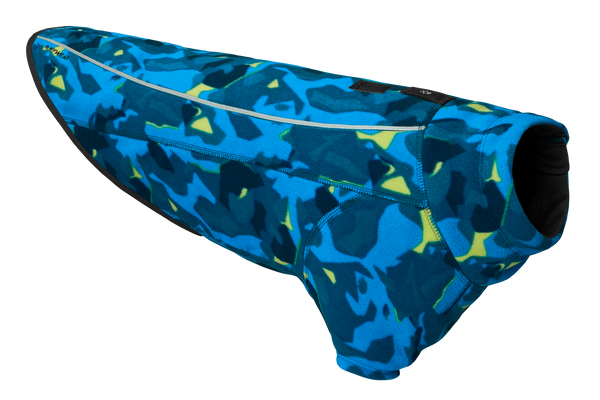

As we do, you’ll start to see “bluesign® approved material” in our materials list more and more. When you do, it's a good indicator that you're on the right track when looking to make environmentally-minded choices for your dog's gear.